Thermal shock resistance of additive manufactured Inconel 718 by concentrated solar energy

Resumen

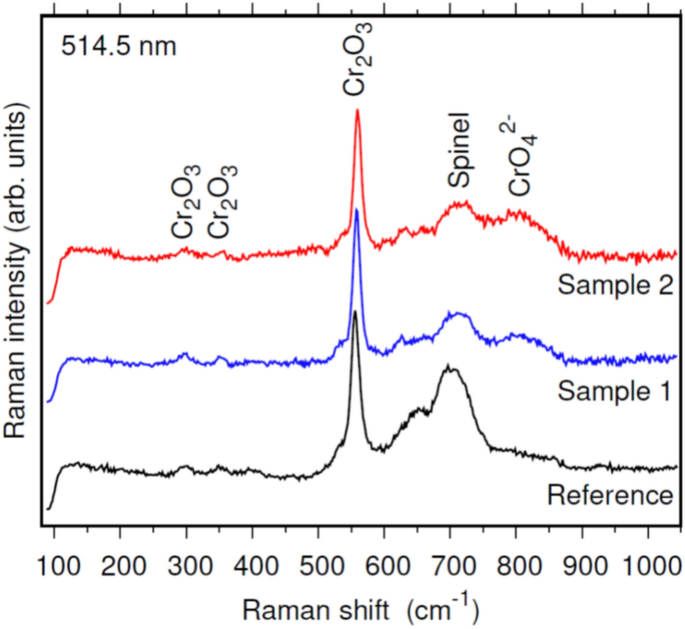

Concentrated Solar Power (CSP) is a powerful tool for simulating the extreme high-temperature conditions that metallic materials encounter. Using a vertical parabolic solar furnace, it was possible to perform heating and cooling cycles between 250 and 950 °C in approximately 250 s per cycle. This capability is particularly relevant for the development of solar receivers used in solar thermal plants. Additive Manufacturing (AM) offers the potential to create new compositions and geometries that can enhance the efficiency of these solar receivers. In this study, Ni-base superalloys—identified as suitable materials for high-temperature solar receivers—were produced using AM and tested in two conditions: as-built and after thermal treatment. These were compared with a forged reference alloy. The results revealed the formation of a protective oxide layer on the surface in all cases. However, the oxide layer on the samples fabricated by additive manufacturing appeared to be more compact and adherent compared to that formed on the reference alloy.

Full citation

J. de Damborenea, A. Conde, G. P. Rodriguez-Donoso, F. Agulló-Rueda, and M. A. Arenas,

“Thermal shock resistance of additive manufactured Inconel 718 by concentrated solar energy,”

Scientific Reports, 15, 7557 (2025).

DOI: 10.1038/s41598-025-92332-x